Chlorate Overview

A chlorate oxidizer that enables fast and stable etching by containing etching acceleration components

and complexing-agent components.

It can stably maintain the oxidizer concentration and keep the ORP value steady.

| Item | Details |

|---|---|

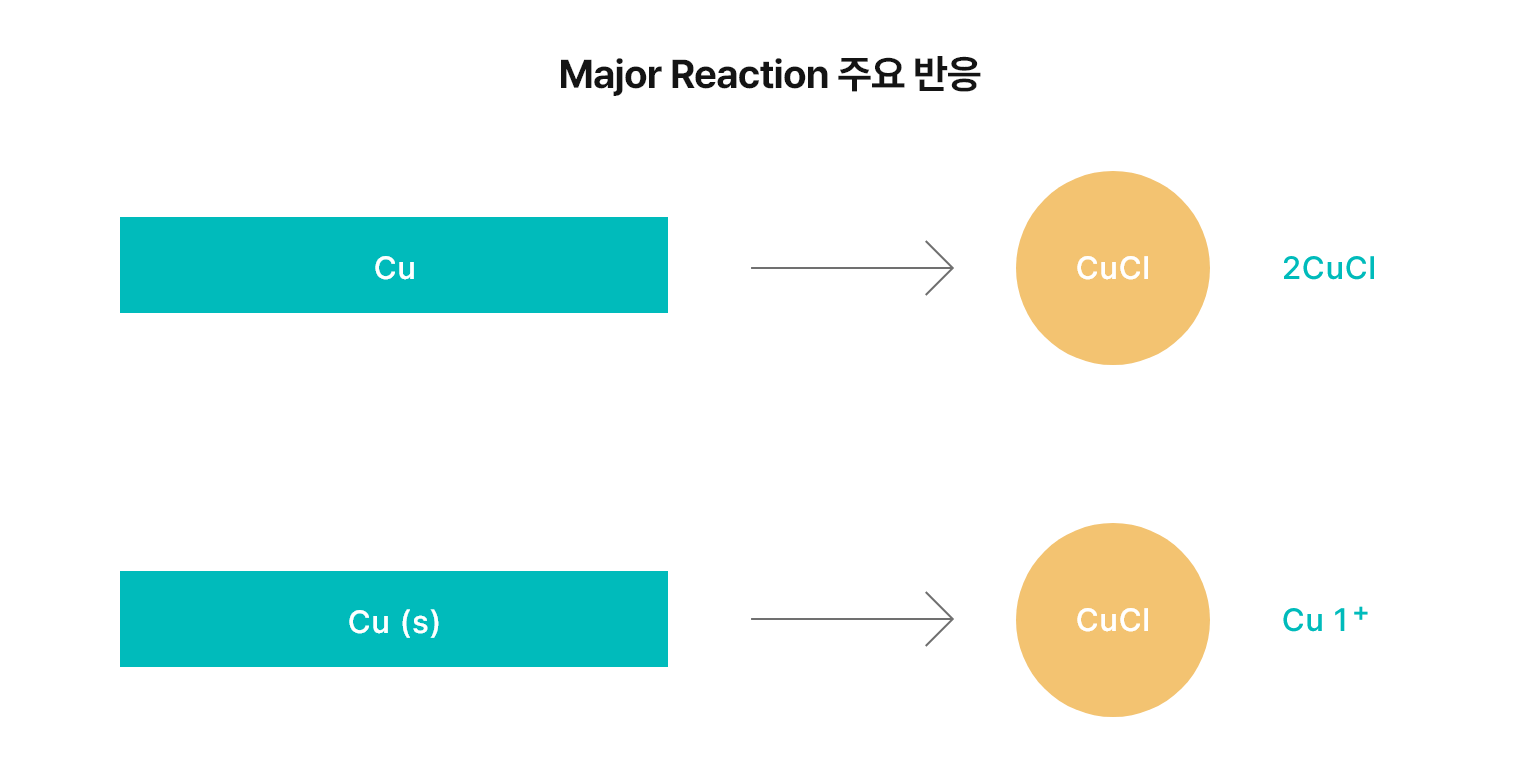

| Applicable Process | Pattern, Copper (Cu) etching process (CuCl₂ copper chloride etchant) |

| Product Form | Liquid additive |

| Applicable Lines | Tenting process: HDI, Package, MLB, FPC, RF-PCB |

| Component | Role |

|---|---|

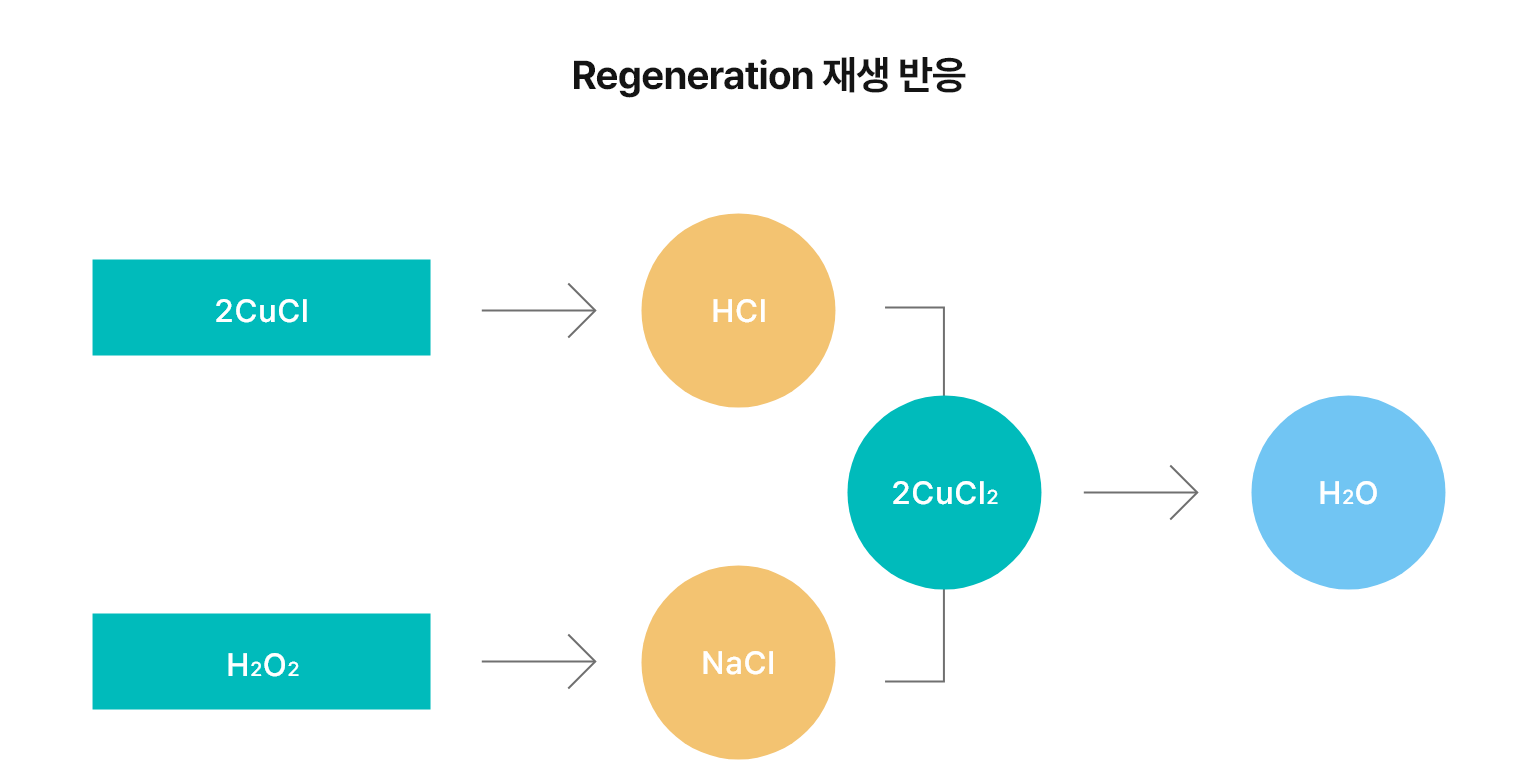

| Sodium Chlorate (NaClO₃) | Maintains the oxidizing power of the etchant and serves as a regenerating agent |

| Hydrogen Peroxide (H₂O₂) |

Chlorate Evaluation Results

Etching Speed Comparison (vs. H₂O₂)

When the HCl value is the same, NaClO3 chlorate secures a faster etching speed than the peroxide type.

Etching Condition

| SG : 1.270 ~ 1.280 | Pressure : 1.25~1.30 kgf/㎠ | Temp : 48 ~ 49℃ | Specimen : L/S=75/75㎛ (1 oz. =35㎛) |

| HCL Conc. (N) |

Etch Rate Vs Oxidizer |

SPEED UP (%) | |

|---|---|---|---|

| H₂O₂ | NaClO₃ | ||

| 1.5 | 0.57 | 0.71 | 24 |

| 2.0 | 0.63 | 0.82 | 30 |

| 2.5 | 0.72 | 0.86 | 20 |

| 3.0 | 0.76 | 0.93 | 20 |

| 3.5 | 0.86 | 0.95 | 10 |

H₂O₂ Type vs NaClO₃ Oxidizer Etching Speed

| Category | H2O2 | NACLO3 | H₂O₂ | NACLO₃ |

|---|---|---|---|---|

| #1 | #2 | |||

|

|

|

|

|

| S.G | 1.270 | 1.270 | 1.275 | 1.275 |

| HCL | 2.5N | 1.5N | 3.5N | 2.5N |

| ORP | 560 ~ 650 mV | 560 ~ 580 mV | 560 ~ 600 mV | 560 ~ 600 mV |

| Etching Depth | 21.55 ㎛ | 21.26 ㎛ | 25.86 ㎛ | 25.86 ㎛ |

| E/R | 0.72 ㎛/sec | 0.71 ㎛/sec | 0.86 ㎛/sec | 0.86 ㎛/sec |