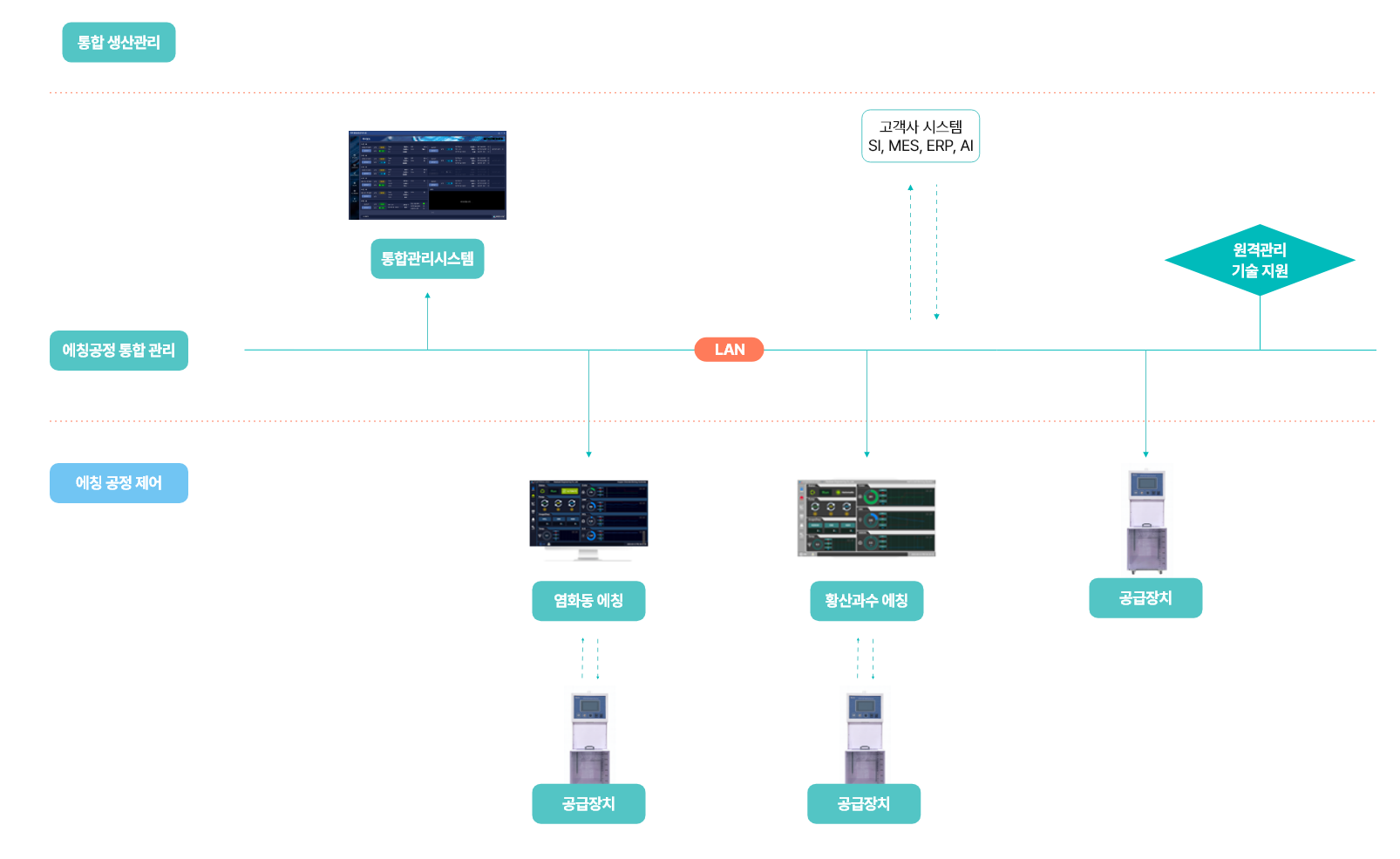

LINK SYSTEM

This is a total solution for etching process management.

• Integrated etching process management software (HMI), Edge-AI prediction/control algorithms, control platform, and dedicated sensors adopted

• System selection available depending on operational objectives such as fine patterns and cost efficiency

• Standalone operation or integrated operation is possible for each system

Applied Technologies

Integrated monitoring, control, and management functions for the entire line in the control room

Predicts the optimal timing for chemical dosing (automatic optimization reflecting line characteristics)

- Various functions can be added or changed by modifying software on the same hardware

- Remote software download and control algorithm changes (customer specifications can be reflected)

- Application of non-contact technologies such as optical, RF, and ultrasonic technologies (reliability)

- Improved measurement precision by applying high-resolution sensor elements and communication methods with no transmission loss

Provides systems suitable for various etching methods such as cupric chloride, soft etching, and half etching

Expected Benefits

| Improved (Stabilized) Etching Quality |

Stable process maintenance is possible by applying reliable measurement information and AI technology Improved uniformity of etching patterns |

|---|---|

| Reduced Maintenance/Management Costs |

Reduced management costs (process maintenance and management) Optimized control of chemical consumption Reduced manufacturing costs due to fewer failures and lower defect rates (improved line utilization) |

| Fast and Accurate System Management via Remote Technical Support |

Supports customer-centered after-service management methods such as prompt A/S and remote operation support (Option) |

| Integration Support with Customer Systems such as uSI and MES |

Real-time and historical information can be utilized |

Integrated Management System

Cupric Chloride Etching

Sulfuric Acid–Hydrogen Peroxide Etching

Supply Unit

Link System Components

| Configuration | Description |

|---|---|

| Integrated Management System | Software that integrates and manages the entire system |

| Etching System (Cupric Chloride, Sulfuric Acid–Hydrogen Peroxide) | Equipped with an optimal control algorithm based on customer operating conditions |

| Chemical (Additive) Supply Unit | Supplies chemicals such as etching additives and controls concentration |

| Various Sensors and Transmitters | Sensors based on communication and standard inputs (current, voltage) |