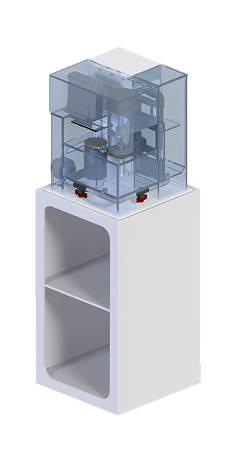

· Installation and protection for various sensors

· For cupric chloride etching

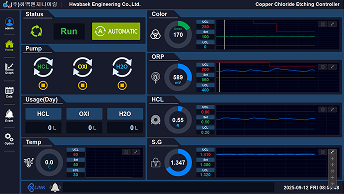

· Monitoring and control

· For cupric chloride etching

· Various control algorithms can be downloaded

Overview

· Etching control/management system based on sodium chlorate (NaClO₃) and hydrochloric acid (HCl)

· Maintains stable etching conditions through continuous management of oxidation/reduction reactions (stabilized etching quality, improved uptime) / Composed of a measuring tank, HMI, and controller

· Applies high-precision sensors and a software-based platform (Controller)

· Applies prediction and control technology based on artificial intelligence (Edge-AI)

· Provides various operation/management information to support stable operation

· Applies a communication-type sensor method that prevents transmission loss of sensor measurement values

· Improves complex control functionality and control reliability by adopting dual sensors: ORP / RGB

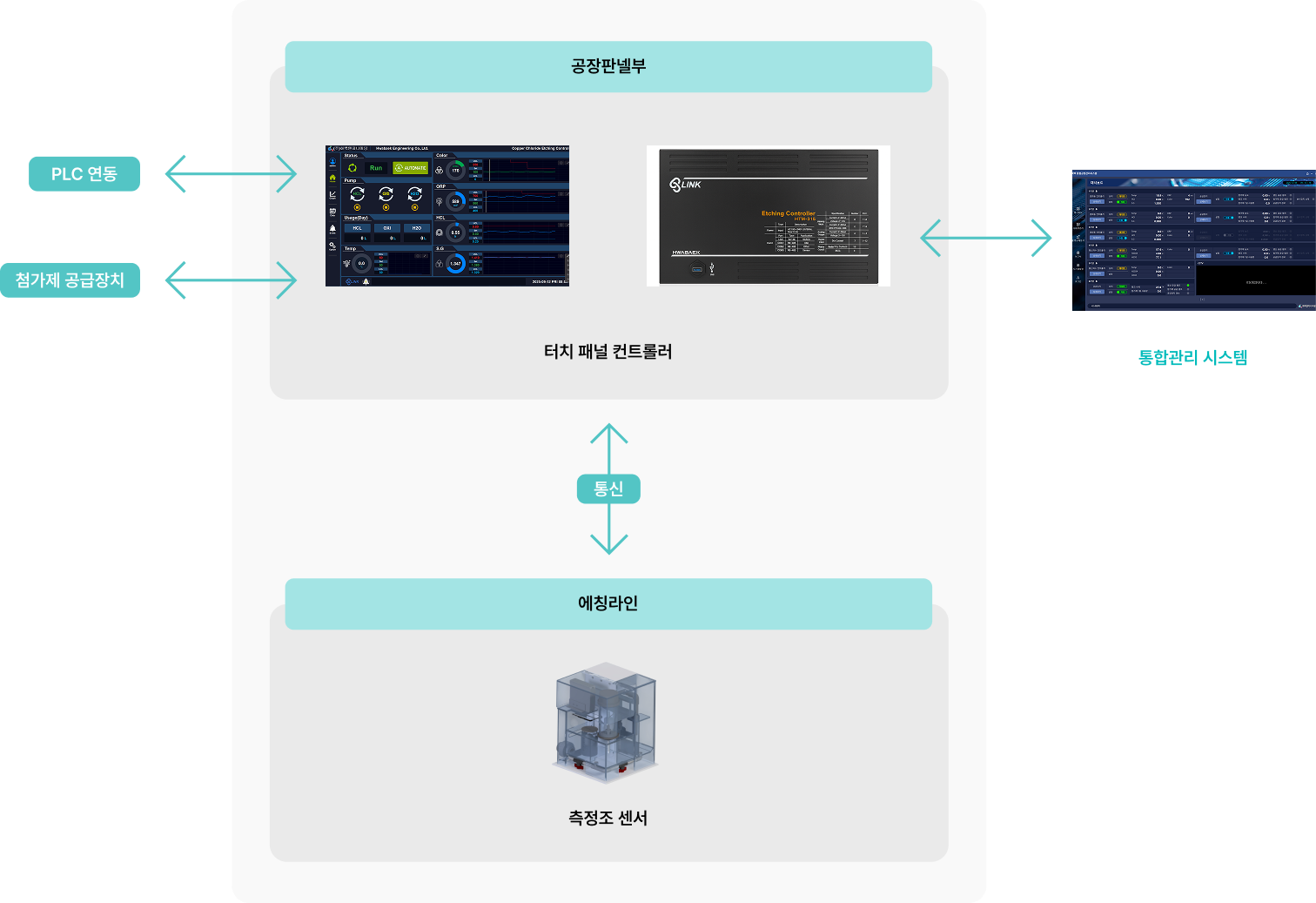

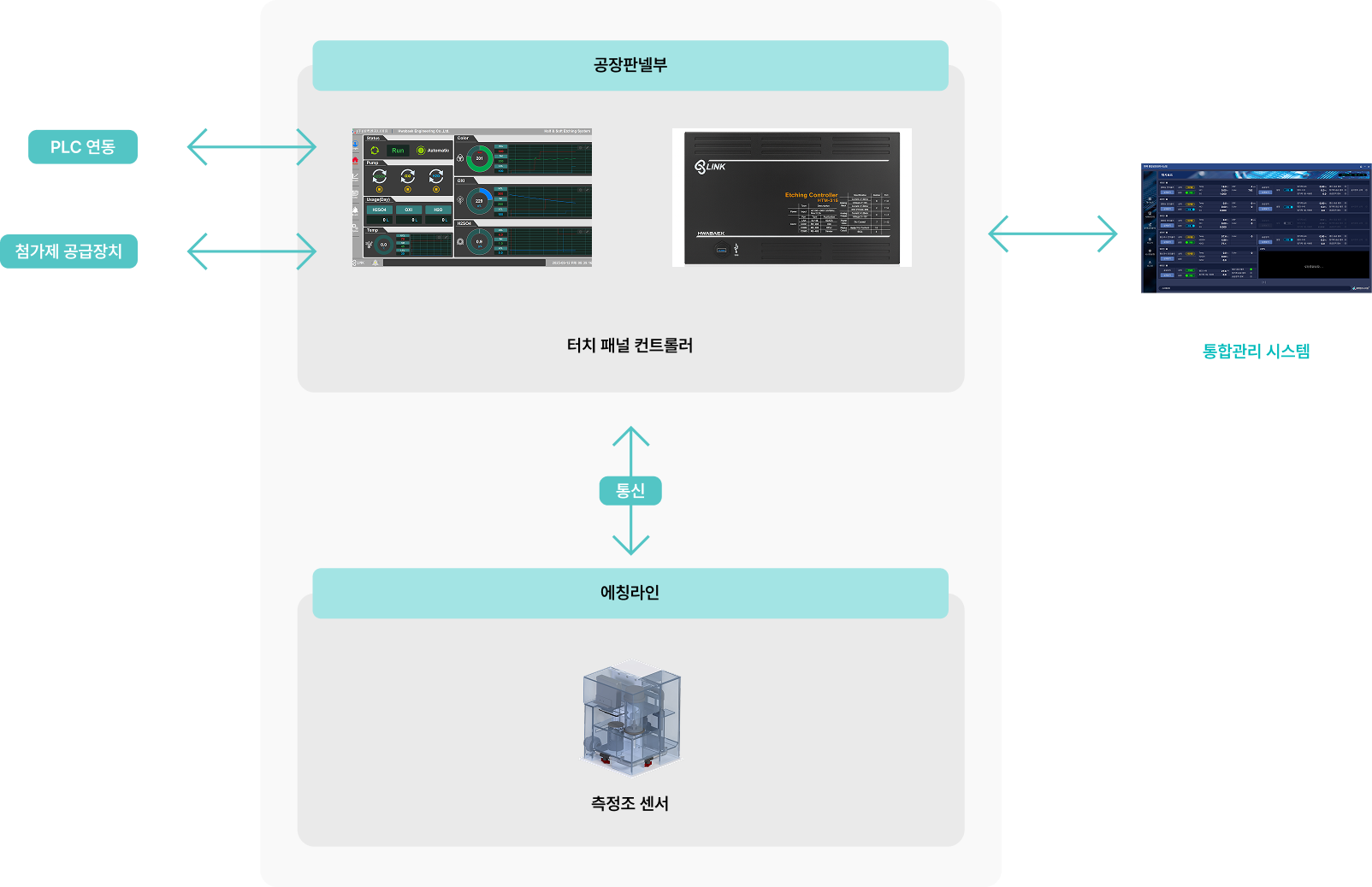

Structure of the Cupric Chloride Etching System

Main Screen

Usage Management

History Screen

Analysis Screen

· Separate installation structure for the sensor installation part (measuring tank) and the control part (on-site panel installation)

· Adoption of a dedicated HMI for real-time control and management

· Control device applying universal control platform technology (software-centric controller)

· Provides operating data storage and various analysis functions

· Software download function via communication (additional algorithm downloads by company)

· Enhanced sensor reliability through optical specific-gravity sensors, communication-type sensors, etc.

· Provides various system status information (alarms, status analysis and logging functions)

· Interlocked control function with supply unit: shares sensor information and control functions

· Sensors: ORP, conductivity, specific gravity, RGB, temperature sensors, and PCB copper-clad laminate (CCL) count applied

Product Specifications

| Classification | Specification | Others | |

|---|---|---|---|

| Control & Management | On-site operation/management (HMI) | 15.6 inch (FHD) touch panel | Dedicated HMI for sulfuric acid–hydrogen peroxide etching installed |

| Control unit | Universal platform (HAC-300A) | Software-defined controller | |

| Communication | LAN * 2, RS-485 * 3 | Integrated management system Communication-type sensors, Supply unit / other system interfaces |

|

| H₂O₂ Sensor | Measuring tank | Water tank for sensor installation | PVC material |

| Specific gravity sensor | Optical specific gravity sensor | Communication type | |

| RGB sensor | Analog data of individual R, G, B colors | Communication type | |

| H2O2 sensor | Platinum, KCL solution (replaceable measuring tip) | Communication type | |

| Conductivity sensor | Electromagnetic induction method | Replaceable measuring tip | |

| Temperature sensor | PT1000 | 4 ~ 20 mA | |

| Photo Sensor | Counter | Installed on the etching line | |

| Table | Dedicated table for installing the measuring tank | - | |

· Installation and protection for various sensors

· For sulfuric acid–hydrogen peroxide etching

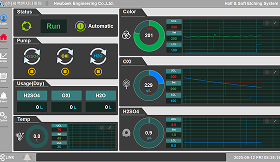

· Monitoring and control

· For sulfuric acid–hydrogen peroxide etching

· Software defined Controller

Overview

· Etching control/management system based on low-concentration hydrogen peroxide (H2O2) and sulfuric acid (H2SO4)

· Maintains stable etching conditions through continuous management of oxidation/reduction reactions (stabilized etching quality, improved uptime)

· Composed of a measuring tank, HMI, and controller

· Supports Half Etching and Soft Etching

· Applies high-precision sensors and a software-based platform (Controller)

· Applies prediction and control technology based on artificial intelligence (Edge-AI)

Structure of the Sulfuric Acid–Hydrogen Peroxide Etching System

Main Screen

Usage Management

History Screen

· Separate installation structure for the sensor installation part (measuring tank) and the control part (controller line installation)

· Adoption of a dedicated HMI for real-time control and management

· Control device applying universal control platform technology (software-centric controller)

· Provides operating data storage and various analysis functions

· Software download function via communication (additional algorithm downloads by company)

· Enhanced sensor reliability through optical specific-gravity sensors, communication-type sensors, etc.

· Provides various system status information (alarms, status analysis and logging functions)

· Interlocked control function with supply unit: shares sensor information and control functions

· Sensors: H2O2, conductivity, specific gravity, RGB, temperature sensors, Photo Sensor (PCB Count) applied

Product Specifications

| Classification | Specification | Others | |

|---|---|---|---|

| Control & Management | On-site operation/management (HMI) | 15.6 inch (FHD) touch panel | Dedicated HMI for sulfuric acid–hydrogen peroxide etching installed |

| Control unit | Universal platform (HAC-300A) | Software-defined controller | |

| Communication | LAN * 2, RS-485 * 3 | Integrated management system Communication-type sensors, Supply unit / other system interfaces |

|

| Measuring Unit (Sensors) | Measuring tank | Water tank for sensor installation | PVC material |

| Specific gravity sensor | Optical specific gravity sensor | Communication type | |

| RGB sensor | Analog data of individual R, G, B colors | Communication type | |

| H₂O₂ sensor | Platinum, KCL solution (replaceable measuring tip) | Communication type | |

| Conductivity sensor | Electromagnetic induction method | 4 ~ 20 mA | |

| Temperature sensor | PT1000 | 4 ~ 20 mA | |

| Photo Sensor | Counter | Installed on the etching line | |

| Table | Dedicated table for installing the measuring tank | - | |