· All-in-one (sensor, controller, HMI)

· Monitoring and control

Overview

· Additive supply and concentration maintenance unit to improve PCB etching quality

· Concentration control algorithm using flow rate or pump operating time, etc. (flow type, basic type)

· Automatic / manual control modes

· High-precision flow sensor applied

· Clamp-on sensor installation method that does not require piping work

· High reliability secured by adopting non-contact sensors (RF, ultrasonic)

· Provides reliability and operational convenience based on an integrated platform

· Large-capacity additive tank

· Redundant tank level control and setting functions (level sensor, float sensor)

Main Screen

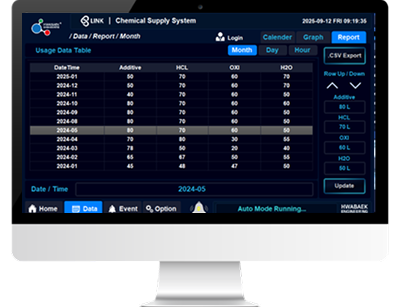

Usage Management

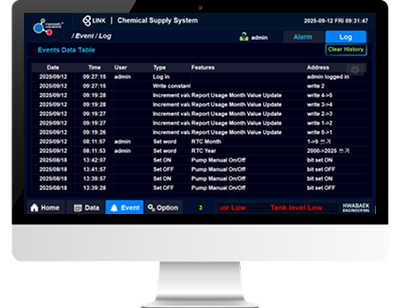

Event Management Screen

Functions / Features

· All-in-one unit: additive tank, measurement & control, and HMI (standalone installation type)

· Flow type or basic type selectable depending on usage

· Adoption of a dedicated HMI for real-time control and management

· Can be operated in an integrated manner with the etching system

· Clamp-on sensor attached externally to the piping without cutting or connecting pipes

· Provides operating data storage and various analysis functions

· Enhanced reliability by adopting non-contact sensors

· Provides various system status information (alarms, status analysis and logging functions)

Product Specifications

| Classification | Specification | Others | |

|---|---|---|---|

| Control & Management | On-site operation/management (HMI) | 10.1-inch touch panel |

Dedicated HMI for the supply unit installed Monitoring function for analysis unit (optional) |

| Control unit | Universal platform (HAC-300A) | Add/change functions via software download | |

| Communication | LAN, RS-485 * 3 | ||

| Sensors | Flow sensor | Ultrasonic sensor | Pulse input |

| Analog level sensor | RF sensor | 4 ~ 20 mA | |

| Digital level sensor (emergency) | Float type | Contact type | |

| Tank Capacity | Capacity of additive storage tank | Max: 140, Typical usage: 120 | |