Product : HCE-300

Product Name : HCE-300

A copper etchant that can selectively and uniformly remove copper or copper alloys in fine circuit processes for semiconductors and displays,

while maintaining a fast etch rate and minimizing undercut with a sidewall protection function.

Product Information

| Item | Features |

|---|---|

| Component Type | Hydrogen Peroxide–Acid based |

| Metal Selectivity | Provides selective and uniform etching performance for copper or copper alloys |

| Etching Speed | Maintains fast etch speed, advantageous for forming precise microstructures |

| Surface Roughness | Uniform etching maintains fine and consistent circuit surface roughness |

| Contaminant Removal | Excellent removal of organic/inorganic contaminants such as copper oxide films and resist residues |

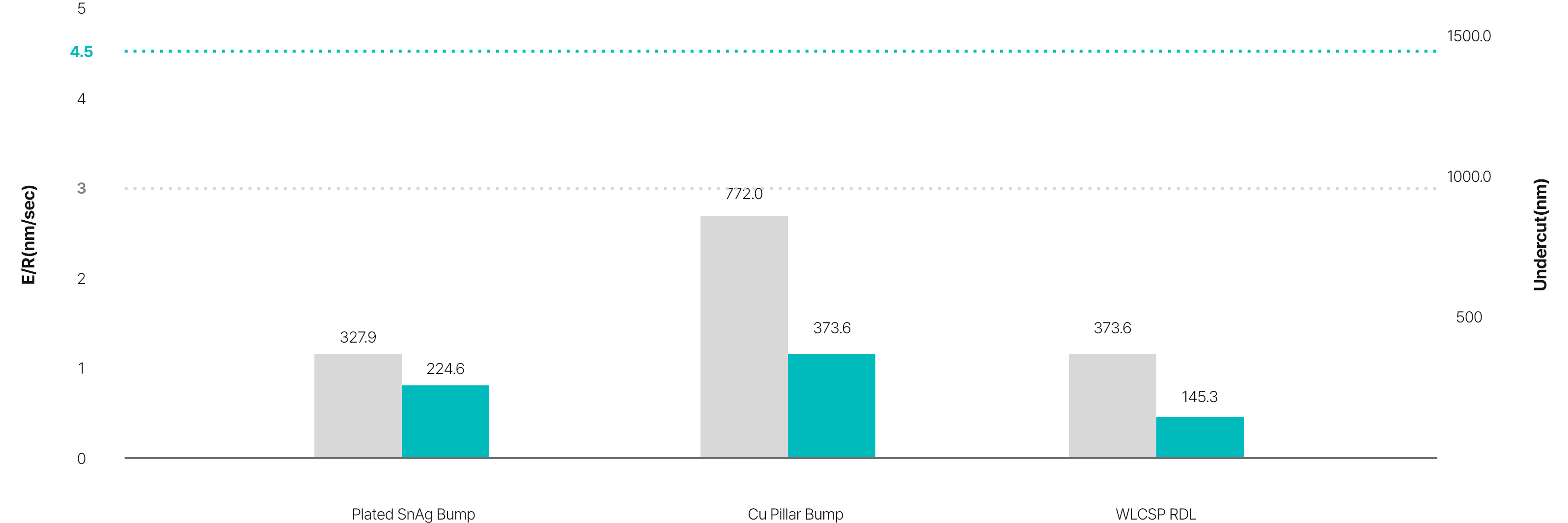

Mechanism

Oxidation of the copper surface by hydrogen peroxide

Acid dissolves and removes the oxidized copper layer

Complexing agents stabilize the dissolved copper ions

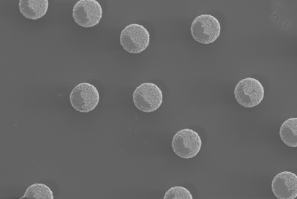

Sputtered Cu Layer Etch Chemical for WLCSP

Thickness Range

(Thk. : 100~500nm)

Eco-friendly (F-free)

Process Applicable

Metal Damage Free

(SnAg, Ni, Au, Al, Ti, Ti-W)

Enables Finer, More Precise

Patterns than Competitors

Excellent

Process Capacity

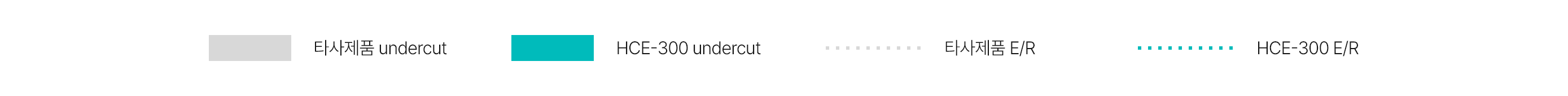

| Product | Evaluation Item | Plated SnAg Bump | Cu Pillar Bump | WLCSP RDL |

|---|---|---|---|---|

| Competitor | E/R (nm/sec) | 3 | 3 | 3 |

| Undercut (nm) (O/E : 200%) |

327.9 | 772.0 | 373.6 | |

| HCE-300 | E/R (nm/sec) | 4.5 | 4.5 | 4.5 |

| Undercut (nm) (O/E : 200%) |

224.6 (-31.5%) | 373.6 (-51.6%) | 145.3 (-61%) |

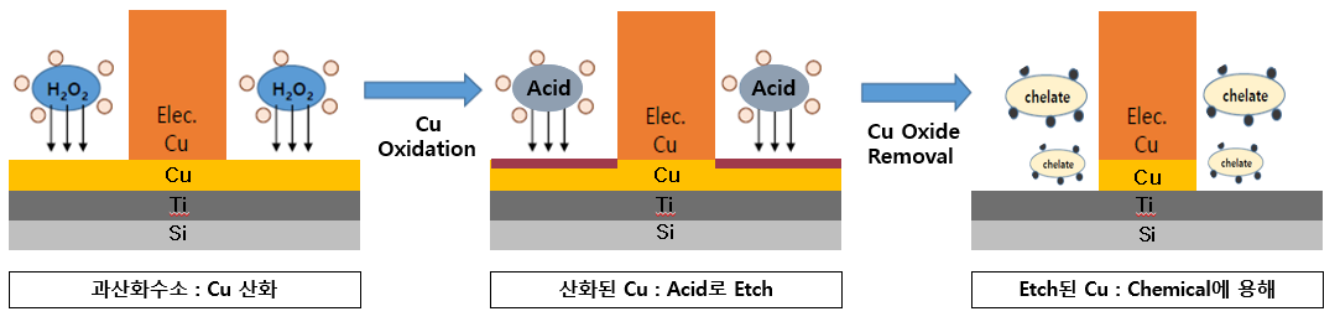

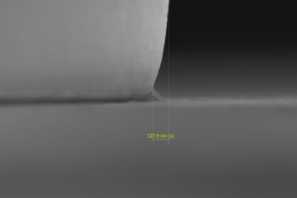

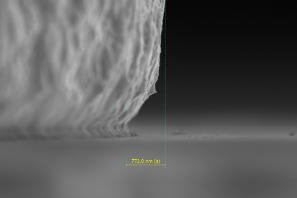

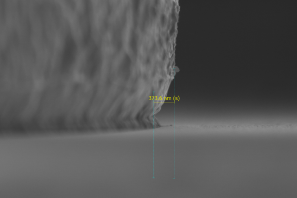

| Plated SnAg Bump | Cu Pillar Bump | WLCSP RDL | |

|---|---|---|---|

| Wafer |  |

|

|

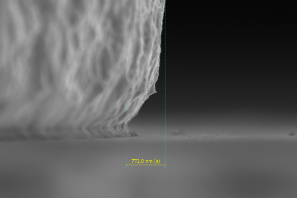

| Competitor Undercut |

|

|

|

| 327.9 nm | 772.0 nm | 373.6 nm | |

| HCE-300 Undercut |

|

|

|

| 224.6 nm | 373.6 nm | 145.3 nm |

Comparison of E/R and Undercut by Sample Type