HTE-100

Product : HTE-100

Sputtered Ti Layer Etch Chemical for WLCSP (Thk. : 50~150nm)

Thickness Range

(Thk. : 50~150nm)

Eco-friendly (F-free)

Process Applicable

Metal Damage Free

(SnAg, Ni, Au, Al, Cu)

Enables Finer, More Precise

Patterns than Competitors

Excellent

Process Capacity

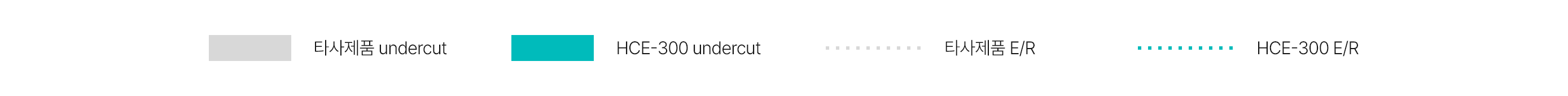

| Product | Evaluation Item | WLCSP RDL |

|---|---|---|

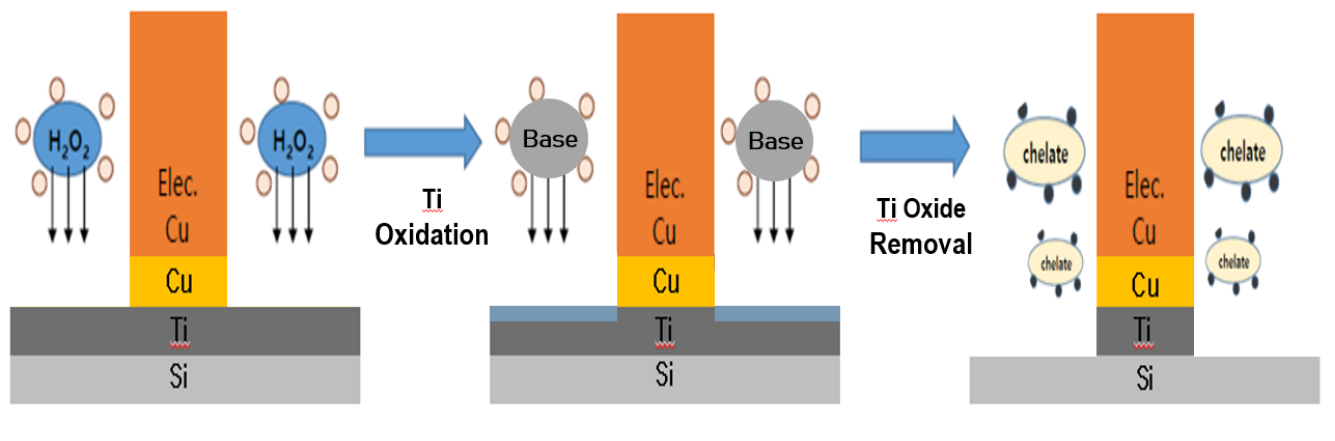

| Competitor | E/R (nm/sec) | 2.0 |

| Undercut (nm) | 298.8 (O/E : 300%) | |

| HTE-100 | E/R (nm/sec) | 2.2 |

| Undercut (nm) | 265.6 (O/E : 300%) |

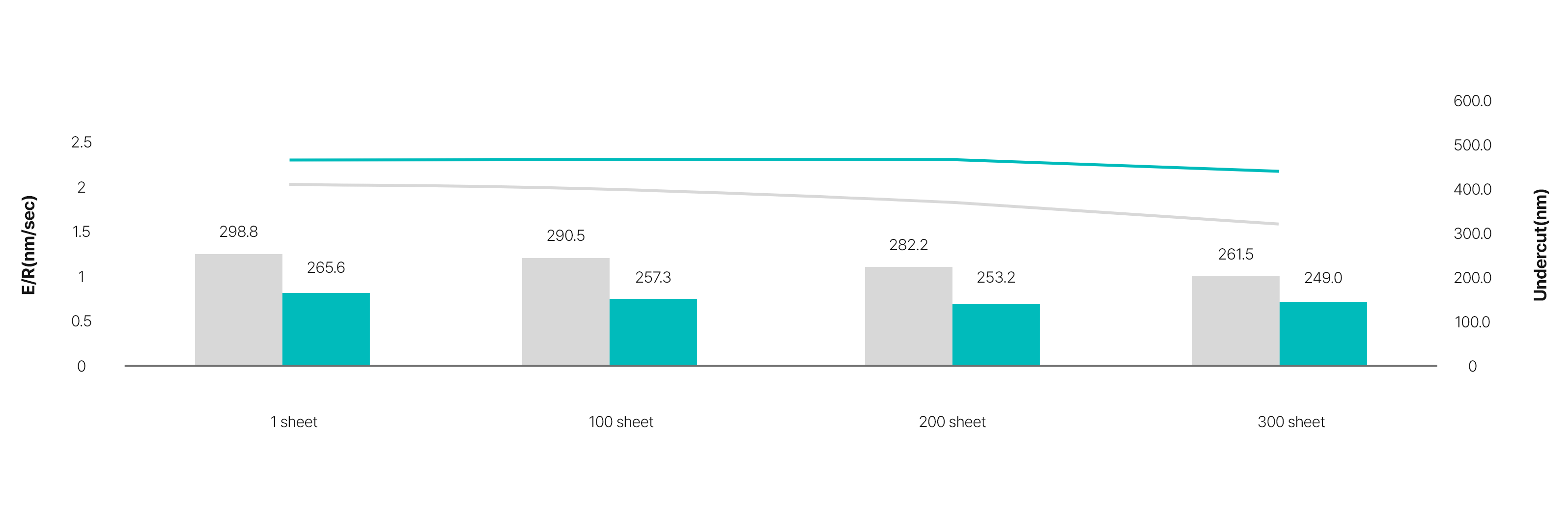

Mechanism

Oxidation of the titanium surface by hydrogen peroxide

Base dissolves and removes the oxidized titanium layer

Complexing agents stabilize the dissolved titanium ions

| Capacity | 1 Sheet (300% over etch) |

100 Sheets (300% over etch) |

200 Sheets (300% over etch) |

300 Sheets (300% over etch) |

|---|---|---|---|---|

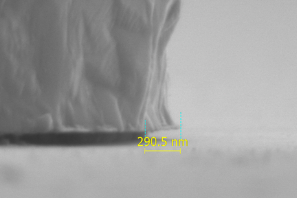

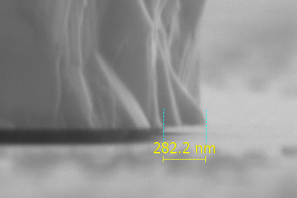

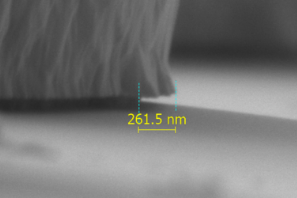

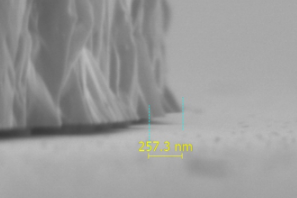

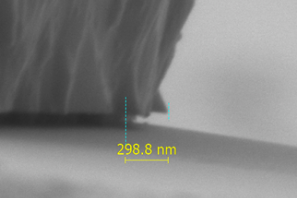

| Competitor Undercut |

|

|

|

|

| 298.8 nm | 290.5 nm | 282.2 nm | 261.5 nm | |

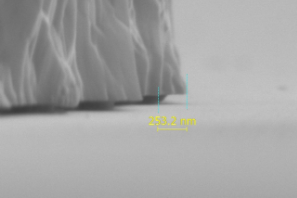

| HTE-100 Undercut |

|

|

|

|

| 265.6 nm | 257.3 nm | 253.2 nm | 249.0 nm | |

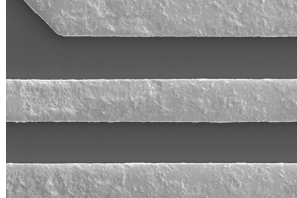

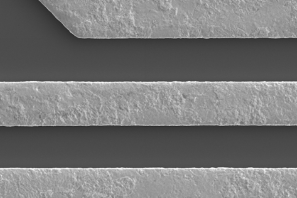

| Ti Residue |

|

|

|

|

| No Residue | ||||

Comparison of E/R and Undercut by Processing Capacity